I started this shield close to four years ago. Judging by period art, crescent shields were used from Thrace to western Scythia and possibly even Persia itself, but to my knowledge no archaeological example has been found. I think - again judging by art - that most of them were made of true wicker, especially around the Aegean. However, this one is intended for reenactment combat, and not having the luxury to replace my shield every time, I decided to start with a solid wood core. It's made of two layers of 1/4-inch poplar planks glued up with a modern waterproof carpenter glue, and then cut on a bandsaw, with the edges rounded but no tapering.

The front is a goat rawhide drum cover attached with hide glue and stitched with waxed linen cord. I had to spread the glue right up to the edges and weigh them down so they didn't peel away while drying. It's painted with a simple mix of red ochre and boiled linseed oil in the area within the stitching, and commercial white oil paint on the edges. I've found no clearly-attested shield devices from the Persian empire, so after a while spent wondering whether to use a Thracian device or a Persian motif that hasn't been found on shields, I decided to leave it plain.

Before attaching the front, I had to do the backing and then the grip and armbands. The back is linen, attached with wood glue and then covered in acrylic paint. Since beginning this shield, I've tried to use more period-appropriate materials; if I were starting from square one today, I would've used linseed oil and yellow ochre on the back. The grip and armband are chrome-tanned leather attached with clinched nails, the grip wrapped in German buckskin with a wrist pad of the same held on by cut tacks.

Wrapping the upper corners with the rawhide left some gaps, which I packed with resin-beeswax hot glue and melted with the heat gun to fill in after the paint had cured. Lastly, I rubbed the stitching, facing and facing edges with linseed oil-beeswax sealer, which is why the yellow back is slightly darker near the edges. Total weight is 2 pounds 13 ounces (almost 1.28kg), width 20 inches (51cm), height 17 inches (43cm). I suspect that originals were both larger and lighter (or at least proportionally lighter). This shield is sized for me, especially the armbands and grips. It may be difficult to use for someone whose forearms are a different length or thickness. It's possible that the grips and armbands on true wicker shields could be re-tied to loosen, tighten or even move to a different place, though this was probably hard to do once the hide facing was attached.

As is usually the case with rawhide facings applied wet, the shield has wound up curved slightly concave as the facing dried and shrank. The more you stretch the facing, the more it will warp; excessive shrinkage can even destroy the wooden core.

A guide to the Achaemenid Persian empire for reenactors, focusing on the Graeco-Persian Wars period. A quick guide to Persian history, society, religion, military, clothing and culture, plus links to reenactment groups and commemorations of the 2,500th anniversary of the Graeco-Persian Wars.

Monday, December 7, 2020

Sunday, November 8, 2020

Product review: Lord of Battles forged medium spearhead

Spearheads are a dime a dozen on the reenactor market, but it's strangely difficult to find one that's quite right for our time period. The vast majority are either too large, the wrong shape, or very expensive. In fact, India-based manufacturer Lord of Battles' forged medium spearhead is the only one I've found in its price bracket that looks approximately right (though if you have another example, I'd be much obliged if you'd let me know!).

Judging by the finds from Deve Hüyük and elsewhere, the typical Achaemenid spearhead should be relatively small (usually less than a foot long counting the socket) and have narrow kite- or leaf-shaped blades with diamond cross sections, preferably but not always with a mid-rib. I know of only two whose weights are published, at 196g/6.91oz. and 139.2g/4.91oz. They may have weighed more before corrosion, but I would imagine the upper weight should be well under 300 grams or 11 ounces for an average-sized spearhead.

Lord of Battles' low prices are presumably a result of lower labor costs than in Western countries, loose manufacturing tolerances (i.e. the company will accept more pieces from workshop[s] despite pieces not being exactly what they should be) and rough finish (less labor required in absolute terms). I say all this to explain why I think this spearhead is the way it is.

I bought mine through Kult of Athena, who list it at 11.5 inches overall, blade 6.5 inches, socket about 1 inch on the inside, weight 6.7 ounces. The measurements of the one I received are 11.75 inches overall, blade 7.125 inches, socket 1 inch on the inside, weight almost 11 ounces. The blade also appears to be wider and more sharply tapered. Mine also lacks the advertised rivet hole to help attach it to the spear shaft, and the socket isn't quite circular. Combining all this with fact that one edge is visibly concave and the centerline is curved, I'm left with a poor impression of Lord of Battles' quality control.

The size differences are minor and the asymmetrical appearance might be considered forgivable considering how cheap the spearhead is, but the weight difference (at least for someone like me) is pretty significant. We are talking about something you affix to the end of a 6+ foot handle and wave around in one hand. The edges are pretty thick and the point is squared-off, so thinning and slight re-profiling with an angle grinder or belt sander might noticeably improve it. (In fact, while parts of the spearhead may indeed be forged, I suspect the blade was shaped largely by grinding to begin with. The fact that it has a rough-ground finish doesn't help that impression.) At this price, someone who is set up for that kind of work already might consider it a bargain, and aftermarket finishing would certainly improve its appearance.

Judging by the finds from Deve Hüyük and elsewhere, the typical Achaemenid spearhead should be relatively small (usually less than a foot long counting the socket) and have narrow kite- or leaf-shaped blades with diamond cross sections, preferably but not always with a mid-rib. I know of only two whose weights are published, at 196g/6.91oz. and 139.2g/4.91oz. They may have weighed more before corrosion, but I would imagine the upper weight should be well under 300 grams or 11 ounces for an average-sized spearhead.

Lord of Battles' low prices are presumably a result of lower labor costs than in Western countries, loose manufacturing tolerances (i.e. the company will accept more pieces from workshop[s] despite pieces not being exactly what they should be) and rough finish (less labor required in absolute terms). I say all this to explain why I think this spearhead is the way it is.

I bought mine through Kult of Athena, who list it at 11.5 inches overall, blade 6.5 inches, socket about 1 inch on the inside, weight 6.7 ounces. The measurements of the one I received are 11.75 inches overall, blade 7.125 inches, socket 1 inch on the inside, weight almost 11 ounces. The blade also appears to be wider and more sharply tapered. Mine also lacks the advertised rivet hole to help attach it to the spear shaft, and the socket isn't quite circular. Combining all this with fact that one edge is visibly concave and the centerline is curved, I'm left with a poor impression of Lord of Battles' quality control.

The size differences are minor and the asymmetrical appearance might be considered forgivable considering how cheap the spearhead is, but the weight difference (at least for someone like me) is pretty significant. We are talking about something you affix to the end of a 6+ foot handle and wave around in one hand. The edges are pretty thick and the point is squared-off, so thinning and slight re-profiling with an angle grinder or belt sander might noticeably improve it. (In fact, while parts of the spearhead may indeed be forged, I suspect the blade was shaped largely by grinding to begin with. The fact that it has a rough-ground finish doesn't help that impression.) At this price, someone who is set up for that kind of work already might consider it a bargain, and aftermarket finishing would certainly improve its appearance.

Friday, September 4, 2020

Waterproof hot glues

IMPORTANT NOTE (3/22/21): Since publishing this article, I have learned that pine rosin fumes have been found to cause asthma. The process described below should always be done outdoors. If weather doesn't permit, then postpone it.

This year I've been trying to eliminate any period-inappropriate materials from my designs. One that's stuck with me for a long time is rubber cement, which I've used to attach leather facings to wooden scabbards. I use it primarily because in a real military campaign you couldn't reasonably expect to stash away your scabbard every time it rained, and rubber cement is waterproof, while for a long time the only alternative that came to mind was hide glue, which isn't. (I understand traditional hide glue is less readily water-soluble than the modern kind that I've been using, which has urea added to keep it liquid at room temperature - traditional hide glue must be kept warm to work with it.)

Anyway, I've read years ago about making varnish from pine rosin by dissolving it in alcohol. This can be used to protect sinew wrappings on arrows from softening and coming loose. It recently occurred to me to ask if this varnish would be sufficiently sticky to use for scabbard facings before it dried. I was in the process of making a new letter opener, and it seemed like the right opportunity to try it out.

If you've ever touched a sawn-off stump of a pine tree, you know that pine resin is incredibly sticky and impossible to wash off with normal soap and water; you need highly-concentrated alcohol (70+ percent hand sanitizer gel works well for this purpose) or some other nasty organic solvent like acetone (nail polish remover). Resin consists largely of rosin, the solid component, and turpentine, a natural solvent that keeps the resin liquid. Turpentine takes a long time to evaporate out of fresh pine resin, so resin is processed commercially by heating in a still. Those who aren't trying to collect the turpentine just cook it off in an open pot.

I ordered some rosin from Creekwood Naturals for experimentation. This product arrives as a coarse, sandy powder. It becomes sticky when wet, but it seems to be waterproof.

My first experiments went thusly: I dissolved some rosin in rubbing alcohol and let it evaporate to a thick, syrupy consistency that could be painted onto a scrap of sanded poplar plank. For comparison, I also smeared some fresh pine resin on the wood, alongside rubber cement. On top of all three adhesives I pressed a tiny swatch of chamois, then let the substances dry.

The fresh resin took the longest to dry. After several days, all three swatches peeled off easily. The resin was still slightly sticky under the leather; the rosin brittle; the rubber cement, well, rubbery.

I'd heard that beeswax is often used in rosin-based pitch glues to reduce the rosin's brittleness, so my next test used a mix of alcohol-rosin varnish reduced to a syrup and a bit of Sno Seal, which is emulsified beeswax used to waterproof shoes. This did not work out at all. The mix took forever to dry, and wasn't sticky enough.

Giving up on emulsions, I decided to try a hot glue. I shaved some beeswax into a metal bowl and, working by eye, added about two to three times its volume in rosin, then slowly melted the bowl's contents with a heat gun. At first, the beeswax melted while the rosin turned into a sticky mess, but with prolonged heating and stirring with a brass rod, the mixture became uniform. (It also released fumes that stung my eyes, and when hot enough, began to smoke.) Then I smeared a little onto the poplar and quickly stuck the chamois swatch onto it.

I repeat: Wow! Once cool, the glue bonded the chamois to the wood with immense strength. When I tried to peel it, the leather itself ripped up before the glue failed. I can dent the glue with my nail, but it's not sticky, and even though it's mostly rosin, it more resembles very hard, dark beeswax.

It seemed perfect, but now was time for the real test.

Earlier, I'd ordered a piece of pitch glue to try to glue the wooden halves of a scabbard core together. It was tricky. I warmed the glue, pinched off thin bits and laid them on the edges of one half, then melted them with the heat gun and quickly pressed the halves together. Then I had to heat each edge in turn and press it more tightly, and scrape off or press down the lumps of glue sticking out of the seam. I also had to shoot the heat gun into the scabbard, then stick the blade in to force any inward-protruding lumps aside and keep a good fit.

When it came time to apply the facing, I melted the entire bowl of rosin-beeswax mix, let it cool to a consistency sort of like room-temperature corn syrup, and smeared it as evenly as possible on the core with the brass rod in one-inch stages. I melted it again with the heat gun, then pressed on the leather. When each half of the facing had been applied, I heated the whole face evenly and pressed it against a flat surface to try to smooth out the lumps of glue that had built up underneath. The result was still somewhat lumpy. Finally, I stitched up the facing with linen thread in a double-running stitch, and trimmed off the excess.

My heavy reliance on a heat gun does call into question the practicality of this kind of glue in period. Trying to do the same thing over open flames might well be difficult, as may trying this method on a larger, more complex scabbard such as one for an akinakes. Nonetheless, when the time comes, this will be what I try.

I have no doubt that this glue will prove waterproof. Even if it becomes slightly sticky in the rain, the idea of it bleeding through the leather is inconceivable to me. To my mind, the real test will be whether it softens after a few hours in the hot sun, for which purpose I'll have to wait for the right weather.

As for the letter opener itself: The blade is another full-tang dagger blade from Atlanta Cutlery, with maple scales and steel pins. I did reshape the tang to be a little more like a classic Luristan dagger, but while it affects a Near Eastern Iron Age look and I'm using it as a test bed for period materials, I don't believe this object bears sufficient resemblance to any Achaemenid-period dagger to warrant actually using it at reenactments. (I would, however, love to be proven wrong.)

As an aside, I've bought four Windlass Steelcraft blades this year, and their geometry seems to have worsened compared to my previous purchases, with slightly thinner spines and much thicker, squared edges that will take forever to sharpen.

The scabbard, with its central ridge, straight lines down the edges (here interpreted as facing seams), and rounded tip without a chape, is modeled after those shown in Neo-Assyrian art such as the Lion Hunt of Ashurbanipal and at the Palace of Sargon II. Its core is made from American commercial poplar (tulipwood), probably yellow poplar, which is simply the low-end hardwood we usually get in my part of the country.

This year I've been trying to eliminate any period-inappropriate materials from my designs. One that's stuck with me for a long time is rubber cement, which I've used to attach leather facings to wooden scabbards. I use it primarily because in a real military campaign you couldn't reasonably expect to stash away your scabbard every time it rained, and rubber cement is waterproof, while for a long time the only alternative that came to mind was hide glue, which isn't. (I understand traditional hide glue is less readily water-soluble than the modern kind that I've been using, which has urea added to keep it liquid at room temperature - traditional hide glue must be kept warm to work with it.)

Anyway, I've read years ago about making varnish from pine rosin by dissolving it in alcohol. This can be used to protect sinew wrappings on arrows from softening and coming loose. It recently occurred to me to ask if this varnish would be sufficiently sticky to use for scabbard facings before it dried. I was in the process of making a new letter opener, and it seemed like the right opportunity to try it out.

If you've ever touched a sawn-off stump of a pine tree, you know that pine resin is incredibly sticky and impossible to wash off with normal soap and water; you need highly-concentrated alcohol (70+ percent hand sanitizer gel works well for this purpose) or some other nasty organic solvent like acetone (nail polish remover). Resin consists largely of rosin, the solid component, and turpentine, a natural solvent that keeps the resin liquid. Turpentine takes a long time to evaporate out of fresh pine resin, so resin is processed commercially by heating in a still. Those who aren't trying to collect the turpentine just cook it off in an open pot.

I ordered some rosin from Creekwood Naturals for experimentation. This product arrives as a coarse, sandy powder. It becomes sticky when wet, but it seems to be waterproof.

My first experiments went thusly: I dissolved some rosin in rubbing alcohol and let it evaporate to a thick, syrupy consistency that could be painted onto a scrap of sanded poplar plank. For comparison, I also smeared some fresh pine resin on the wood, alongside rubber cement. On top of all three adhesives I pressed a tiny swatch of chamois, then let the substances dry.

The fresh resin took the longest to dry. After several days, all three swatches peeled off easily. The resin was still slightly sticky under the leather; the rosin brittle; the rubber cement, well, rubbery.

I'd heard that beeswax is often used in rosin-based pitch glues to reduce the rosin's brittleness, so my next test used a mix of alcohol-rosin varnish reduced to a syrup and a bit of Sno Seal, which is emulsified beeswax used to waterproof shoes. This did not work out at all. The mix took forever to dry, and wasn't sticky enough.

Giving up on emulsions, I decided to try a hot glue. I shaved some beeswax into a metal bowl and, working by eye, added about two to three times its volume in rosin, then slowly melted the bowl's contents with a heat gun. At first, the beeswax melted while the rosin turned into a sticky mess, but with prolonged heating and stirring with a brass rod, the mixture became uniform. (It also released fumes that stung my eyes, and when hot enough, began to smoke.) Then I smeared a little onto the poplar and quickly stuck the chamois swatch onto it.

I repeat: Wow! Once cool, the glue bonded the chamois to the wood with immense strength. When I tried to peel it, the leather itself ripped up before the glue failed. I can dent the glue with my nail, but it's not sticky, and even though it's mostly rosin, it more resembles very hard, dark beeswax.

It seemed perfect, but now was time for the real test.

Earlier, I'd ordered a piece of pitch glue to try to glue the wooden halves of a scabbard core together. It was tricky. I warmed the glue, pinched off thin bits and laid them on the edges of one half, then melted them with the heat gun and quickly pressed the halves together. Then I had to heat each edge in turn and press it more tightly, and scrape off or press down the lumps of glue sticking out of the seam. I also had to shoot the heat gun into the scabbard, then stick the blade in to force any inward-protruding lumps aside and keep a good fit.

When it came time to apply the facing, I melted the entire bowl of rosin-beeswax mix, let it cool to a consistency sort of like room-temperature corn syrup, and smeared it as evenly as possible on the core with the brass rod in one-inch stages. I melted it again with the heat gun, then pressed on the leather. When each half of the facing had been applied, I heated the whole face evenly and pressed it against a flat surface to try to smooth out the lumps of glue that had built up underneath. The result was still somewhat lumpy. Finally, I stitched up the facing with linen thread in a double-running stitch, and trimmed off the excess.

My heavy reliance on a heat gun does call into question the practicality of this kind of glue in period. Trying to do the same thing over open flames might well be difficult, as may trying this method on a larger, more complex scabbard such as one for an akinakes. Nonetheless, when the time comes, this will be what I try.

I have no doubt that this glue will prove waterproof. Even if it becomes slightly sticky in the rain, the idea of it bleeding through the leather is inconceivable to me. To my mind, the real test will be whether it softens after a few hours in the hot sun, for which purpose I'll have to wait for the right weather.

As for the letter opener itself: The blade is another full-tang dagger blade from Atlanta Cutlery, with maple scales and steel pins. I did reshape the tang to be a little more like a classic Luristan dagger, but while it affects a Near Eastern Iron Age look and I'm using it as a test bed for period materials, I don't believe this object bears sufficient resemblance to any Achaemenid-period dagger to warrant actually using it at reenactments. (I would, however, love to be proven wrong.)

As an aside, I've bought four Windlass Steelcraft blades this year, and their geometry seems to have worsened compared to my previous purchases, with slightly thinner spines and much thicker, squared edges that will take forever to sharpen.

The scabbard, with its central ridge, straight lines down the edges (here interpreted as facing seams), and rounded tip without a chape, is modeled after those shown in Neo-Assyrian art such as the Lion Hunt of Ashurbanipal and at the Palace of Sargon II. Its core is made from American commercial poplar (tulipwood), probably yellow poplar, which is simply the low-end hardwood we usually get in my part of the country.

Saturday, August 22, 2020

Making a leather pocket, part II and last

Stitching on the bottom panel went faster than I expected, and by Noon yesterday I was able to get to work on the final steps.

The original had, as far as I can guess from the photos, eight slits on each side for the drawstring. I spaced my markings out 7/8 inch (22mm) apart and wound up with nine on each side. However, this was a miscalculation; since the drawstring should start and finish on the outside, the final pair went unused. I made the slits with a fresh pointed X-Acto blade, pushed through against a wood "working" block. Older blades tend to break at the very tip, leaving the point squared-off - even if the squaring is so tiny that it looks pointed, it's not as good at piercing. Working by eye, I made each slit around 5/8 inch (16mm) tall and spaced 5/8 inch from the top edge. After penciling a guideline on the rough side, but otherwise working freehand, I added the decorative piercings below the drawstring slits with a hobby awl. They weren't very visible, so I enlarged them with a thicker round scratch awl.

The original had, as far as I can guess from the photos, eight slits on each side for the drawstring. I spaced my markings out 7/8 inch (22mm) apart and wound up with nine on each side. However, this was a miscalculation; since the drawstring should start and finish on the outside, the final pair went unused. I made the slits with a fresh pointed X-Acto blade, pushed through against a wood "working" block. Older blades tend to break at the very tip, leaving the point squared-off - even if the squaring is so tiny that it looks pointed, it's not as good at piercing. Working by eye, I made each slit around 5/8 inch (16mm) tall and spaced 5/8 inch from the top edge. After penciling a guideline on the rough side, but otherwise working freehand, I added the decorative piercings below the drawstring slits with a hobby awl. They weren't very visible, so I enlarged them with a thicker round scratch awl.

The final touch is a drawstring, in the form of a German buckskin thong from Crazy Crow, of which I have several, so I selected the thickest (some of them seem much too thin for this purpose). It may be better to replace it with something less stretchy later. A wool or soft linen/hemp string about a quarter-inch thick might work well here, though I might worry that they would wear at the chamois. The German buckskin has the same texture and softness as the chamois, so my guess is they should wear at each other at about the same rate.

Friday, August 21, 2020

Making a leather pocket, part I

About a year ago, I discussed a leather drawstring pocket found at Elephantine, Egypt, and compared it to a readymade bag from Crazy Crow that I thought would make a passable substitute. I felt at the time that it wouldn't be difficult to make a more authentic replica, and since I have a few spare days, it seemed like now was the moment to go ahead with that.

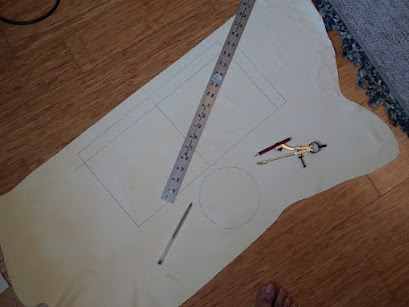

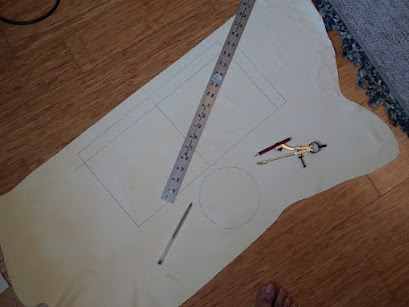

Based on the dimensions of the Crazy Crow bag, a replica should be a hair larger to accommodate things that you wouldn't want to leave unattended, including a phone, passport, wallet and spare cash. I turned the readymade bag inside-out and measured its full height at 6.25 inches (17.22cm) and width at 4.75 inches (12.06cm), and increased them to 7 and 5 inches (17.78 and 12.7cm). Admittedly, this effort is a little undone by the fact that I'm leaving a wider seam of almost 1/4 inch (0.63cm) due to my leather being so thin. By my calculations, a bag with a 5-inch bottom panel should have a circumference (and thus length of the walls) of 15.71 inches (39.9cm); however, it might've been a good idea to leave about an inch extra to account for all the seams. We'll see what happens.

Normally I would suggest feeling all the pieces of chamois and selecting the heaviest one. However, Ace has now begun to package their chamois in plastic bags, so it was no longer possible to confidently make a selection by touch. To make the most of the material I got, I laid out the lines around the middle, where the hide is thickest. It seems to me just barely thick enough for this purpose. The leftovers can be used for facing small knife sheaths, adding sand gussets to chukkas, and other light-duty uses.

The only compass I currently have isn't sized to hold a normal writing pen, so I just scraped the pencil lightly against the suede and then tried to re-draw it freeform. As usual, the lines are drawn on the rougher side, though it bears mentioning that the difference in texture between the two sides of a double-sueded fat-cured leather is, in my experience, much less than that between the two sides of most chrome-tanned splits (which tend to have a nice suede side and an ugly, stringy one).

Based on the dimensions of the Crazy Crow bag, a replica should be a hair larger to accommodate things that you wouldn't want to leave unattended, including a phone, passport, wallet and spare cash. I turned the readymade bag inside-out and measured its full height at 6.25 inches (17.22cm) and width at 4.75 inches (12.06cm), and increased them to 7 and 5 inches (17.78 and 12.7cm). Admittedly, this effort is a little undone by the fact that I'm leaving a wider seam of almost 1/4 inch (0.63cm) due to my leather being so thin. By my calculations, a bag with a 5-inch bottom panel should have a circumference (and thus length of the walls) of 15.71 inches (39.9cm); however, it might've been a good idea to leave about an inch extra to account for all the seams. We'll see what happens.

Normally I would suggest feeling all the pieces of chamois and selecting the heaviest one. However, Ace has now begun to package their chamois in plastic bags, so it was no longer possible to confidently make a selection by touch. To make the most of the material I got, I laid out the lines around the middle, where the hide is thickest. It seems to me just barely thick enough for this purpose. The leftovers can be used for facing small knife sheaths, adding sand gussets to chukkas, and other light-duty uses.

The only compass I currently have isn't sized to hold a normal writing pen, so I just scraped the pencil lightly against the suede and then tried to re-draw it freeform. As usual, the lines are drawn on the rougher side, though it bears mentioning that the difference in texture between the two sides of a double-sueded fat-cured leather is, in my experience, much less than that between the two sides of most chrome-tanned splits (which tend to have a nice suede side and an ugly, stringy one).

Also as usual, stitching is done inside-out, with the rougher side and its ink lines turned inward when done. Chamois is thin enough to push the needle through without pre-piercing holes. The original bag had a rand on only one side seam. I started with the simpler seam, stitching with buttonweight linen thread (not multi-ply cord this time) and re-waxing as I went with a blob of Victory Brown wax that I have on hand - it's softer than beeswax, so it's easier to use for this purpose. The original pocket apparently had a single running stitch, so I knotted the thread at both ends of the seams.

The next step, sewing the bottom seam while inserting the rand on a curve, will probably be the most difficult. I'll work on it today and probably tomorrow as well.

Monday, June 1, 2020

All-steel akinakes by Gladush Dmitry

The akinakai from Deve Hüyük are the best examples known to me this kind of dagger designed for combat in an Achaemenid context. They have plain iron hilts with T-pommels and very short blades which probably reached a maximum of only about 9 inches (23cm) before corrosion, sometimes having low mid-ridges. I think they are likely one of the best choices for a middle-class soldier's sidearm. The design would also work for a Western Scythian impression.

I commissioned this reproduction based an akinakes held at the British Museum from Gladush Dmitry, proprietor of Etsy shop Fantasycraft39, based in Kaliningrad, Russia. Gladush will produce the same design for you on request. The blade is heat-treated 60C2 high-carbon steel. If you only want one for display and non-contact reenactment, a lower price is available for a mild steel blade. Gladush and I discussed the requirements at length; he was very accommodating to my feedback on improvements.

It's vital to note at the outset that due to domestic laws in Kaliningrad Oblast, the dagger ships in two pieces, so you either have to be able to peen the tang yourself (or find a friend who has the tools and knowhow), or weld it. I attempted to peen the tang and failed, so I wound up having it finished by a local welding shop, Weld Republic in Newtown (the proprietor, Glenn, is another fellow I had a great time working with, and his rates are surprisingly cheap). Also, the blade cannot be shipped sharp from Kaliningrad, but the edge isn't terribly thick - it's comparable to the factory edge on an Atlanta Cutlery blade - so sharpening it shouldn't be much trouble.

To improve hold on the grip, I wrapped it in 2mm hemp cord according to an instructional by Tony Drake at RAT (RAT account needed to view full-sized photos; go ahead, it's free). This kind of wrapping would likely need to be replaced periodically as it became grimy or worked loose, but it seems tight enough to last several battles and is only a few minutes' work. Lastly, I filled the slight gap between the guard and blade with beeswax-linseed oil to keep water from getting in and rusting inside the hilt. I suspect a more authentic option, if you can get it, would be something along the lines of melted cutler's resin, put into the hilt before the tang is inserted.

I commissioned this reproduction based an akinakes held at the British Museum from Gladush Dmitry, proprietor of Etsy shop Fantasycraft39, based in Kaliningrad, Russia. Gladush will produce the same design for you on request. The blade is heat-treated 60C2 high-carbon steel. If you only want one for display and non-contact reenactment, a lower price is available for a mild steel blade. Gladush and I discussed the requirements at length; he was very accommodating to my feedback on improvements.

It's vital to note at the outset that due to domestic laws in Kaliningrad Oblast, the dagger ships in two pieces, so you either have to be able to peen the tang yourself (or find a friend who has the tools and knowhow), or weld it. I attempted to peen the tang and failed, so I wound up having it finished by a local welding shop, Weld Republic in Newtown (the proprietor, Glenn, is another fellow I had a great time working with, and his rates are surprisingly cheap). Also, the blade cannot be shipped sharp from Kaliningrad, but the edge isn't terribly thick - it's comparable to the factory edge on an Atlanta Cutlery blade - so sharpening it shouldn't be much trouble.

After assembly. Glenn's weld is completely invisble.

Before assembly.

You'll note that this first edition arrived with edges on the guard that weren't rounded off, but Gladush says that they can be on future daggers, at no additional cost. Also, while the dimensions of this one are in keeping with historical examples, some buyers may wish for slightly different ones, such as a thicker blade (the British Museum example is only 5mm with the mid-ridge and pretty light, but a few others appear to have been thicker) or a different grip length depending on the size of your hand. Again, small adjustments won't increase the price.To improve hold on the grip, I wrapped it in 2mm hemp cord according to an instructional by Tony Drake at RAT (RAT account needed to view full-sized photos; go ahead, it's free). This kind of wrapping would likely need to be replaced periodically as it became grimy or worked loose, but it seems tight enough to last several battles and is only a few minutes' work. Lastly, I filled the slight gap between the guard and blade with beeswax-linseed oil to keep water from getting in and rusting inside the hilt. I suspect a more authentic option, if you can get it, would be something along the lines of melted cutler's resin, put into the hilt before the tang is inserted.

Thursday, May 14, 2020

Ceramic food bowl by Pamela Cummings

Carinated pots and bowls with wide, steep flared rims became common in West Asia in the Iron Age. Moorey in his Deve Hüyük catalogue attributes the style's origin to the Neo-Assyrian empire. They were made of pottery, metal, glass and even stone. While not uniquely Achaemenid, they serve as a good example of a kind of foodware that is often found at Achaemenid sites, and thus will prove useful both as an educational display and, of course, any time you need to eat at an event that's open to the public. Their international status should also make them more versatile for portrayals of people from elsewhere in West Asia in our time period.

I commissioned this bowl from Pamela Cummings, the Harrisburg, PA-based artisan who also made my water bottle last year. It's primarily meant as a personal bowl for barley, stew, porridge (I've recently become a big fan of pease porridge) and other spoon foods, but it could also serve as a small common bowl for nuts or dates. We designed it to be about the size of a cereal bowl, about 4-1/2 inches (11.4cm) across at the narrow carinated point, 6 inches (15.2cm) across at the rim, and 3 inches (7.6cm) deep on the outside. It's based on a number of finds, both metal and ceramic, from Persepolis and Deve Hüyük.

In construction, it closely matches the water bottle. Its walls are of medium thickness - thicker than china but thinner than, for instance, the heavier styles of American stoneware. Also like the bottle, it's made of a faintly speckled, greyish-brown clay with a matte glaze to resemble unglazed, burnished pottery, yet meet modern food safety standards. (If your local potter works in different types of clay, buff and terra cotta would also be acceptable colors.) The compact, deep shape and the rim make it convenient to hold, but it has enough of a flat base to sit on a table.

Also as before, I enjoyed working with Pamela on this project, and highly recommend her work. Her prices are also very reasonable for such important camp items.

I commissioned this bowl from Pamela Cummings, the Harrisburg, PA-based artisan who also made my water bottle last year. It's primarily meant as a personal bowl for barley, stew, porridge (I've recently become a big fan of pease porridge) and other spoon foods, but it could also serve as a small common bowl for nuts or dates. We designed it to be about the size of a cereal bowl, about 4-1/2 inches (11.4cm) across at the narrow carinated point, 6 inches (15.2cm) across at the rim, and 3 inches (7.6cm) deep on the outside. It's based on a number of finds, both metal and ceramic, from Persepolis and Deve Hüyük.

In construction, it closely matches the water bottle. Its walls are of medium thickness - thicker than china but thinner than, for instance, the heavier styles of American stoneware. Also like the bottle, it's made of a faintly speckled, greyish-brown clay with a matte glaze to resemble unglazed, burnished pottery, yet meet modern food safety standards. (If your local potter works in different types of clay, buff and terra cotta would also be acceptable colors.) The compact, deep shape and the rim make it convenient to hold, but it has enough of a flat base to sit on a table.

Also as before, I enjoyed working with Pamela on this project, and highly recommend her work. Her prices are also very reasonable for such important camp items.

Thursday, April 2, 2020

Painted suede is a conditional go

About a year and a half ago, Todd Feinman at RAT told me about a period leather finish that could be made from one part melted beeswax and two parts linseed oil. The oil polymerizes so that the mixture isn't sticky when cured, and the beeswax keeps the mixture flexible.

Regular readers will recall that I've long been troubled by the question of how to reproduce the crenelated decorations frequently seen on Greek depictions of the gorytos. You could stitch on dyed leather or cloth, but that always struck me as needlessly laborious, and very difficult unless the case's main seam were opened up, so I've concentrated on finding a paint that will do the trick. It's my understanding that the gorytos and other such gear were made from soft, sueded leather cured with fat or oil, similar to braintan, so any paint would need to be water-resistant (as braintan-type leather soaks up water like a sponge and is hard to seal) and flexible so as not to flake off. It recently occurred to me that the beeswax-oil sealer might make a good paint binder for that purpose.

I tried it out by mixing a little melted sealer and red ochre (I didn't take measurements, but the amount of ochre wasn't enough to thicken the binder significantly), and when it cooled, rubbing it into a scrap of buckskin, scraping off the excess, and rubbing what was left in again. A few days later, when it felt dry, I cut the scrap in half and rubbed a top coat of unpigmented sealer onto one of the pieces. I also tried "priming" another scrap with sealer before painting it and adding a top coat, and rubbing/scraping/rubbing plain red ochre oil paint onto a third piece, which was also then given a top coat.

Yesterday I put all four pieces into a sink full of water and let them soak for an hour and a half. The result was impressive: None of the paint on any of the four pieces ran, smeared, or softened in water. They had apparently sealed in all the pigment in a good-as-waterproof manner. I even scraped the paints with my fingernail and none came off. The plain oil paint worked just as well when rubbed and scraped instead of merely brushed on, but it cured much stiffer than the beeswax-oil paint, so between the two, I think the beeswax is preferable. The additional top coat was not needed, though I suspect it would make the paint job more durable in the long run. Because German buckskin is so pale, only a little paint is needed.

This technique comes with a number of caveats:

1. I know of no evidence whatsoever that the Persians or anybody else actually used a paint like this in antiquity. The materials would've been available, but I have no reason to think that anyone combined them and used them in this manner, other than that it would've been a great way of making those crenelated bowcase decorations.

2. I used hardware-store boiled linseed oil. This version has some sort of chemical additives that cause it to cure faster than the kind that would've been available in our period, which (if used as a paint binder) would've been functionally equivalent to the purer linseed oil still sold in art stores for making traditional oil paint. In other words, if you use the more period-correct oil, you'll need to allow much more time for it to "dry." On the other hand, it's doubtlessly less toxic.

3. Many leatherworkers believe that linseed oil's chemical properties degrade leather fibers over time. However, I think the paint only soaks in shallowly, so I don't think it'll prove much of a problem.

4. The rubbing and scraping technique is useful only for producing large, simple designs. It may be possible to apply finer oil paint designs on leather that's been glued to a hard surface and primed with drying oil; if so, that technique might be appropriate for scabbard facings glued to a wood core.

Regular readers will recall that I've long been troubled by the question of how to reproduce the crenelated decorations frequently seen on Greek depictions of the gorytos. You could stitch on dyed leather or cloth, but that always struck me as needlessly laborious, and very difficult unless the case's main seam were opened up, so I've concentrated on finding a paint that will do the trick. It's my understanding that the gorytos and other such gear were made from soft, sueded leather cured with fat or oil, similar to braintan, so any paint would need to be water-resistant (as braintan-type leather soaks up water like a sponge and is hard to seal) and flexible so as not to flake off. It recently occurred to me that the beeswax-oil sealer might make a good paint binder for that purpose.

I tried it out by mixing a little melted sealer and red ochre (I didn't take measurements, but the amount of ochre wasn't enough to thicken the binder significantly), and when it cooled, rubbing it into a scrap of buckskin, scraping off the excess, and rubbing what was left in again. A few days later, when it felt dry, I cut the scrap in half and rubbed a top coat of unpigmented sealer onto one of the pieces. I also tried "priming" another scrap with sealer before painting it and adding a top coat, and rubbing/scraping/rubbing plain red ochre oil paint onto a third piece, which was also then given a top coat.

Yesterday I put all four pieces into a sink full of water and let them soak for an hour and a half. The result was impressive: None of the paint on any of the four pieces ran, smeared, or softened in water. They had apparently sealed in all the pigment in a good-as-waterproof manner. I even scraped the paints with my fingernail and none came off. The plain oil paint worked just as well when rubbed and scraped instead of merely brushed on, but it cured much stiffer than the beeswax-oil paint, so between the two, I think the beeswax is preferable. The additional top coat was not needed, though I suspect it would make the paint job more durable in the long run. Because German buckskin is so pale, only a little paint is needed.

This technique comes with a number of caveats:

1. I know of no evidence whatsoever that the Persians or anybody else actually used a paint like this in antiquity. The materials would've been available, but I have no reason to think that anyone combined them and used them in this manner, other than that it would've been a great way of making those crenelated bowcase decorations.

2. I used hardware-store boiled linseed oil. This version has some sort of chemical additives that cause it to cure faster than the kind that would've been available in our period, which (if used as a paint binder) would've been functionally equivalent to the purer linseed oil still sold in art stores for making traditional oil paint. In other words, if you use the more period-correct oil, you'll need to allow much more time for it to "dry." On the other hand, it's doubtlessly less toxic.

3. Many leatherworkers believe that linseed oil's chemical properties degrade leather fibers over time. However, I think the paint only soaks in shallowly, so I don't think it'll prove much of a problem.

4. The rubbing and scraping technique is useful only for producing large, simple designs. It may be possible to apply finer oil paint designs on leather that's been glued to a hard surface and primed with drying oil; if so, that technique might be appropriate for scabbard facings glued to a wood core.

Wednesday, April 1, 2020

The Battle of Talisca

Please read all the way through for a clear understanding of the following article.

I've always found it a bit unfortunate that much of the attention media and even reenactors pay to the Graeco-Persian Wars have been focused on only half a dozen major battles: Marathon, Thermopylae, Artemisium, Salamis, Plataea and Mycale. While a broad understanding of the events leading up to Darius' invasion can be found in the pages of pop history books like Persian Fire, for many writers the wars seem to come to an abrupt end with the defeat of Xerxes' invasion of mainland Greece. Even the period of 490-479 BCE saw multiple sieges and battles at Naxos, Eretria, Karystos, Talisca, Potidaea and Olynthus. Herodotus covered the wars up to the siege of Sestos; the next year, the Peloponnesians and Athenians sailed as far away as Byzantium and Cyprus. The Wars of the Delian League stretched on into the middle of the fifth century and went even farther afield, winding down with the Greeks' failed invasion of Egypt, which many historians mark as the actual end of the Graeco-Persian Wars proper. Why exactly so much of the history hasn't held so much fascination for the rest of us isn't totally clear to me. I suppose part of it has to do with most of the major battles being seen as "turning points," but that's not even true for all of them, like Artemisium.

The Battle of Talisca is one of my favorites. It took place almost as far from Greece as the Siege of Memphis two decades later. It was an aberration: Both armies were isolated, far out of their element, and almost certainly neither actually wanted to fight in a region which neither the Greeks nor Persians ever tried to invade, but I find it all the more interesting because of that. Our chief period source on it is Eurypylus of Miletus (449-394 BCE) who wrote Historia tou Europas ("Inquiries about Europe," or "History of Europe") in or around 415. There is, however, a possible corroboration to be found among the Persepolis Fortification Archive.

According to Eurypylus, after the Battle of Salamis, several Greek and Persian ships were driven northward by a storm up the western coasts of Greece. Their crews beached them on the northern Adriatic shores and disembarked in search of food and directions. The Persians, learning of the Greeks' presence, pursued them, or possibly it was the other way around. Alternately, the two groups ran into each other through blind chance after trying to avoid each other for as long as possible. In any event, they had wandered deep into Europe by the time they finally met in the highlands of what is now Provincia, populated at the time by the Paraseticae.

The Paraseticae were an Indo-European people speaking a language possibly related to Celtic, Illyrian or Germanic. They were an impoverished tribe who subsisted on small farming, herding (mainly of sheep and goats, with small numbers of cattle), and stealing things from their lowland neighbors. Nonetheless the "prince" or chief of the Paraseticae, Golbrantes, sent messengers to two villages telling them to welcome the invaders separately. Eurypylus thinks that Golbrantes had the idea of getting the two armies to fight to the death and then pillaging the dead, but it didn't exactly turn out that way.

War was not the Paraseticae's strong suite. The nearest thing they had to armies were sort of like parties of land-Vikings, but more poorly equipped. They relied on dashing in and overwhelming isolated herders or homesteads, grabbing loot and fleeing back into the highlands while doing as little fighting as possible, and robbing travelers. On top of being too disorganized and few in number to form armies with any clout, one of the most important factors in their inability to wage war was noted by Eurypylus and even Roman writers hundreds of years later to be their limited supply of decent timber trees. The most common tree in Provincia is the so-called brittle oak, whose wood disintegrates when dry and today is a common component of pulp for toilet paper. Most useable wood was used up for looms, tool handles, certain structural parts of houses (other components were made of mud or stone, with thatched roofs), and other places where nothing else would work. As a result their spears were small, thrown javelins were rare because of the risk of breakage and loss, edged weapons usually had grips of bone or horn, and most shields were either hide or woven grass - even wicker or Asian pseudo-wicker are unachievable without a decent resilient wood.

The Paraseticae didn't have a whole lot of metal, either. The largest edged weapons ever excavated from the period are less than 20 inches overall, and no spearheads exceeding the size of a large javelin have been found that aren't of obviously foreign construction. It's possible that relatively wealthy headmen would have been able to equip themselves with looted arms (Provincia borders on areas of the late Hallstatt and La Tene cultures) but the average raider - terms like "soldier" or even "warrior" are not justifiable here - would've been underequipped by the standards of the poorest Greek or Roman skirmisher. No evidence of archery has ever been found in Provincia pre-dating the late Roman period.

The next morning the two armies went ahead and fought just east (or north) of Talisca. Again, both groups were out of their element. Talisca itself was well-defended behind a narrow, fortified pass, so neither force attempted to lodge themselves inside the village, but the uneven and thickly forested ground hindered the hoplites as well as the Persian archers and Phoenician javelineers, while the Paraseticae mercenaries mostly just attacked each other. After fighting all morning with few casualties and no one managing to hold ground, the two groups withdrew to their camps.

At this time one of Mithraphernes' personal retainers, an archer named Aricaspes, convinced him that a mutual retreat would be in their best interests. The opposing captains secretly met in the forest nearer to Talisca and worked out routes back to the Adriatic coast that would avoid their forces crossing paths again. Apollodorus returned to the Peloponnese by the middle of November. Eurypylus says nothing more of the Persian forces, but it's interesting to note that one of the Persepolis administrative tablets, dating to the tenth regnal year of Xerxes (i.e. 477 BCE), is signed by an Arikaašba of Mirkaniya (the Elamite name for Hyrcania). It's possible that this is actually the archer Aricaspes, having returned home and taken up, or more likely resumed, a job as a bureaucrat at Mithraphernes' estate in Hyrcania. Certainly *Arikaspa would be an unusual, though obviously Iranian, name; it appears to mean "whose horse(s) is evil" or simply "bad horse."

Note (April 3, 2024): It's come to my attention that I may have been too deadpan when composing this article. So, just to be crystal clear about what's going on here:

APRIL FOOL'S!

I've always found it a bit unfortunate that much of the attention media and even reenactors pay to the Graeco-Persian Wars have been focused on only half a dozen major battles: Marathon, Thermopylae, Artemisium, Salamis, Plataea and Mycale. While a broad understanding of the events leading up to Darius' invasion can be found in the pages of pop history books like Persian Fire, for many writers the wars seem to come to an abrupt end with the defeat of Xerxes' invasion of mainland Greece. Even the period of 490-479 BCE saw multiple sieges and battles at Naxos, Eretria, Karystos, Talisca, Potidaea and Olynthus. Herodotus covered the wars up to the siege of Sestos; the next year, the Peloponnesians and Athenians sailed as far away as Byzantium and Cyprus. The Wars of the Delian League stretched on into the middle of the fifth century and went even farther afield, winding down with the Greeks' failed invasion of Egypt, which many historians mark as the actual end of the Graeco-Persian Wars proper. Why exactly so much of the history hasn't held so much fascination for the rest of us isn't totally clear to me. I suppose part of it has to do with most of the major battles being seen as "turning points," but that's not even true for all of them, like Artemisium.

The Battle of Talisca is one of my favorites. It took place almost as far from Greece as the Siege of Memphis two decades later. It was an aberration: Both armies were isolated, far out of their element, and almost certainly neither actually wanted to fight in a region which neither the Greeks nor Persians ever tried to invade, but I find it all the more interesting because of that. Our chief period source on it is Eurypylus of Miletus (449-394 BCE) who wrote Historia tou Europas ("Inquiries about Europe," or "History of Europe") in or around 415. There is, however, a possible corroboration to be found among the Persepolis Fortification Archive.

According to Eurypylus, after the Battle of Salamis, several Greek and Persian ships were driven northward by a storm up the western coasts of Greece. Their crews beached them on the northern Adriatic shores and disembarked in search of food and directions. The Persians, learning of the Greeks' presence, pursued them, or possibly it was the other way around. Alternately, the two groups ran into each other through blind chance after trying to avoid each other for as long as possible. In any event, they had wandered deep into Europe by the time they finally met in the highlands of what is now Provincia, populated at the time by the Paraseticae.

The Paraseticae were an Indo-European people speaking a language possibly related to Celtic, Illyrian or Germanic. They were an impoverished tribe who subsisted on small farming, herding (mainly of sheep and goats, with small numbers of cattle), and stealing things from their lowland neighbors. Nonetheless the "prince" or chief of the Paraseticae, Golbrantes, sent messengers to two villages telling them to welcome the invaders separately. Eurypylus thinks that Golbrantes had the idea of getting the two armies to fight to the death and then pillaging the dead, but it didn't exactly turn out that way.

War was not the Paraseticae's strong suite. The nearest thing they had to armies were sort of like parties of land-Vikings, but more poorly equipped. They relied on dashing in and overwhelming isolated herders or homesteads, grabbing loot and fleeing back into the highlands while doing as little fighting as possible, and robbing travelers. On top of being too disorganized and few in number to form armies with any clout, one of the most important factors in their inability to wage war was noted by Eurypylus and even Roman writers hundreds of years later to be their limited supply of decent timber trees. The most common tree in Provincia is the so-called brittle oak, whose wood disintegrates when dry and today is a common component of pulp for toilet paper. Most useable wood was used up for looms, tool handles, certain structural parts of houses (other components were made of mud or stone, with thatched roofs), and other places where nothing else would work. As a result their spears were small, thrown javelins were rare because of the risk of breakage and loss, edged weapons usually had grips of bone or horn, and most shields were either hide or woven grass - even wicker or Asian pseudo-wicker are unachievable without a decent resilient wood.

Archaeological finds show one thing the Paraseticae had which other peoples in the vicinity lacked: vegetable-tanned leather. It was probably made with the country's plentiful supply of brittle oak galls and bark saved as a byproduct of firewood and charcoal. (They also made cookies and dessert porridge with "barley honey," as Eurypylus calls it, produced by the same mashing process as was used to make beer - in other words, malt syrup.) I tooled this belt with Hallstatt-type motifs and finished it with oil and beeswax; no dye is necessary. Belts were said to be laced rather than buckled; Professor Cabrioletta suggested the method you see above.

The Paraseticae didn't have a whole lot of metal, either. The largest edged weapons ever excavated from the period are less than 20 inches overall, and no spearheads exceeding the size of a large javelin have been found that aren't of obviously foreign construction. It's possible that relatively wealthy headmen would have been able to equip themselves with looted arms (Provincia borders on areas of the late Hallstatt and La Tene cultures) but the average raider - terms like "soldier" or even "warrior" are not justifiable here - would've been underequipped by the standards of the poorest Greek or Roman skirmisher. No evidence of archery has ever been found in Provincia pre-dating the late Roman period.

There are two main types and five subtypes of knives known from the early Iron Age of Provincia. Type I had a ring pommel resembling the kind used by neighboring La Tene Celts. Type Ia tended to be slightly larger with a full-profile tang and bone or horn grips, while type Ib had a narrower, thicker tang with no rivet holes and likely would've been wound with cord or leather as a grip. The larger types are probably derived from Hallstatt long knives. Archaeologist Mariul DiMentato dubbed these "fighting knives," though he acknowledged that type IIa was likely mainly intended as a butcher knife and machete, while still able to function as a sidearm for commoners. The much rarer type IIb has a longer, proportionally narrower blade reminiscent of a Khyber knife, and is more likely a true combat weapon, with a thickened spine often exceeding 8mm. It includes the most elaborate and one of the largest knives, the "Vicito sword," which has, unusually, a bronze guard. With the flowing lines of its decorative carving, it dates from somewhat later - perhaps around the turn of the fourth century, by which point the Paraseticae had begun absorbing elements of the more graceful La Tene style. Not pictured: the type IIc, a long thin-bladed knife possibly used for filleting and deboning. Illustrations from DiMentato's "Cultri in Ata di Ferro in Provincia," 1957.

Atlanta Cutlery sells a large "companion" blade which is quite similar to the DiMentato type I. I wanted to give mine bone grips, but I find bone in many ways too irritating to work with: difficult to find in sufficiently large pieces, prone to chipping unless worked slowly, and producing a lingering stench when ground, along with dust which is dangerous to inhale. Instead I used castelo boxwood for a similar pale color.

Hilt carvings throughout the period were highlighted with ochre and/or bone char. The carvings are functional - they make the knife much easier to grip when performing a slashing blow. I also ground a simple ring-pommel knife out of mild steel, with poplar grips. The paint on both hilts is simple red ochre and linseed oil, which dries quite hard. The spear is a forged small spear/javelin head from Lord of Battles, via Kult of Athena, mounted on a four-foot rake handle from Ace that I sanded and refinished with linseed oil. The handle is attached to the shield by grinding it flat on the ends so that it won't rotate, and adding small grooves that the waxed hemp cord is lashed around. Just two grooves are needed at each end.

Still, both the Persians and Greeks managed to recruit a number of native allies or mercenaries, mostly overenthusiastic young people who failed to understand Golbrantes' plan. Guided by the chief's messengers, the two armies converged near the main village Talisca (Taliske), near modern Capotina, around October 13 or 14, 480. Their scouts reported the enemy ahead, with the Persians in the north (or west) and Greeks in the south (or east). That night, several raiding parties avoided each other and snuck into the oppositions' camps. The Persians managed to return unnoticed, carrying off the Athenian captain Apollodorus' favorite blanket. The Greek sortie managed to get as far as smashing some wine bottles that the Persian captain Mithraphernes of Hyrcania had been hoarding for himself. The sound alerted some sentries, but in the dark the javelineers failed to hit the fleeing hoplites.

Eurypylus says that the Paraseticae used small shields of woven grass or leather, without porpakes, and their "princes" had shields with bronze bosses. In high-status graves, the bosses and pins are the only parts of shields that remain even when iron spearheads and knives are also found, indicating that the shields were otherwise wholly organic. The grass shields were exceedingly ineffective. Pictured: Pottery painting showing one raider TK'ing another while their leader is astounded by a dancing woodwose, or something like that. Let's face it, these people were crazy. Scan from Le Parasetici (1994) by Petrul Beolos.

My attempt at a leather shield has been at a standstill since I've been unable to mold the dome high enough to fill the metal boss. As such, I've left the leather pinned to its wooden mold, which has loops of rope nailed and glued on to form the ridges. I forged the boss from 14-gauge jeweler's brass. BCCC lab tech Nick Hesson shaped a wooden grip for me (no bone or metal ones have ever been found in association with shield bosses) and I hand-cut some washers with the intention of setting the grips with long copper rivets.

The next morning the two armies went ahead and fought just east (or north) of Talisca. Again, both groups were out of their element. Talisca itself was well-defended behind a narrow, fortified pass, so neither force attempted to lodge themselves inside the village, but the uneven and thickly forested ground hindered the hoplites as well as the Persian archers and Phoenician javelineers, while the Paraseticae mercenaries mostly just attacked each other. After fighting all morning with few casualties and no one managing to hold ground, the two groups withdrew to their camps.

No wheel-thrown pottery has been found that appears to have made in Provincia until the Medieval period. The vast majority was pinched, coiled or slab-built. This bowl was made for me by Deb Dayhoff of Earth2Table. It's glazed only on the inside; pottery at this time was normally burnished to make it a bit more watertight, rather than glazed, but only glazing meets modern food safety standards. The horn spoon is from Crazy Crow Trading Post.

Bone-beaded fibulae and necklace with waxed hemp cord, and pieced leather bag made of thin buckskin as a substitute for goat and sheep leather.

At this time one of Mithraphernes' personal retainers, an archer named Aricaspes, convinced him that a mutual retreat would be in their best interests. The opposing captains secretly met in the forest nearer to Talisca and worked out routes back to the Adriatic coast that would avoid their forces crossing paths again. Apollodorus returned to the Peloponnese by the middle of November. Eurypylus says nothing more of the Persian forces, but it's interesting to note that one of the Persepolis administrative tablets, dating to the tenth regnal year of Xerxes (i.e. 477 BCE), is signed by an Arikaašba of Mirkaniya (the Elamite name for Hyrcania). It's possible that this is actually the archer Aricaspes, having returned home and taken up, or more likely resumed, a job as a bureaucrat at Mithraphernes' estate in Hyrcania. Certainly *Arikaspa would be an unusual, though obviously Iranian, name; it appears to mean "whose horse(s) is evil" or simply "bad horse."

(left) My reconstruction of a Paraseticae raider. (right) Seal of Arikaašba.

Note (April 3, 2024): It's come to my attention that I may have been too deadpan when composing this article. So, just to be crystal clear about what's going on here:

APRIL FOOL'S!

Subscribe to:

Posts (Atom)